3D Visualization Central Control System

Features

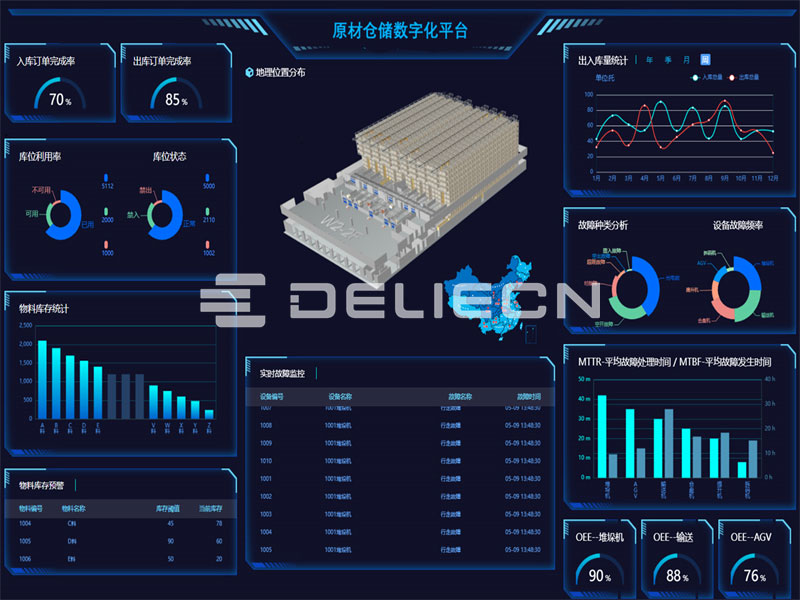

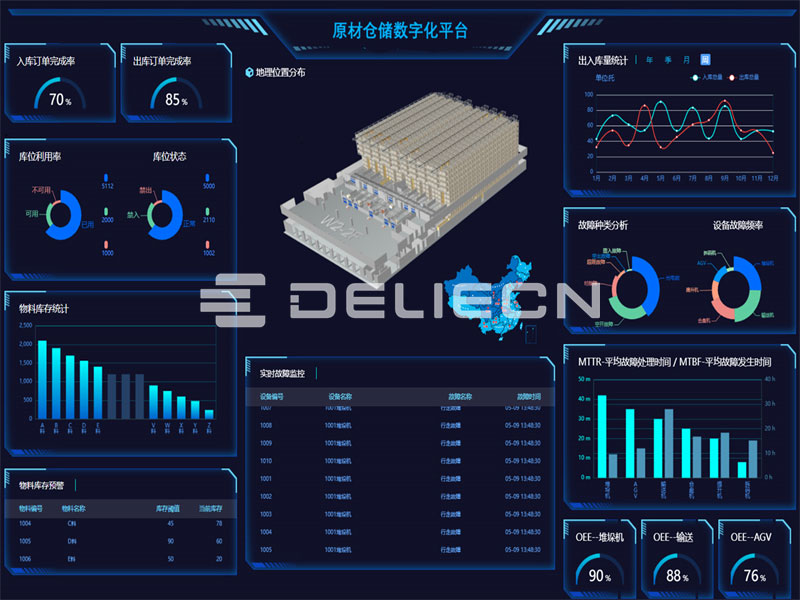

3D visual centralized control system to apply digital twin technology to complete the mapping of physical objects, systems and data in virtual space.

To reflect the whole life cycle process of the corresponding entities, to mine historical patterns, monitor real-time status, and predict future trends.

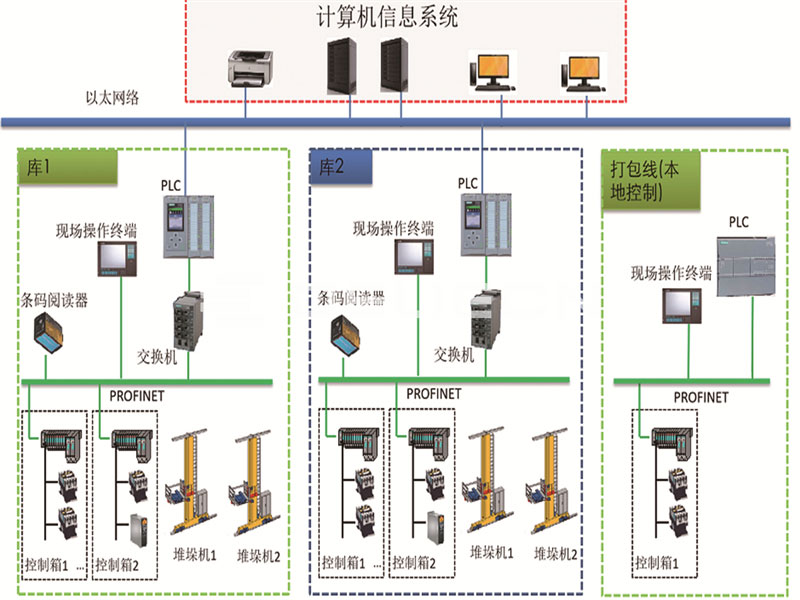

To apply digital twin technology to physical factories to centralize the monitoring, management and maintenance of decentralized systems such as warehousing, logistics and product

- Introduction

Functions

True D model, real scale scaling, real restoration of project scenes.

All-rounddatacollection,visualizationandreal-timemonitoringandmanagementofequipment, information display and query, equipment operation and maintenance management, in-depth data analysis, and full life-cycle prediction.

Panoramic information display by using electronic dashboard, which realizes comprehensive data operation of storage, production and in-plant transportation, solves the problems of production plan postponement,abnormalities and untimely processing, and significantly improves production capacity.

Highly scalable, with diverse interfaces to expand access to different systems, such as security monitoring systems, energy systems, etc.